Custom Hobby Maple Syrup Evaporator

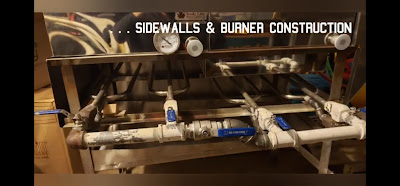

In 2022 I rebuilt this evaporator to accomodate a set of Smoky Lake Dauntless drop flue pans. I added burners, stainless sidewalls, and lengthened the arch.

In 2019, I designed and built a custom hobby maple syrup evaporator to improve efficiency and increase the volume of syrup we could produce. In this post I will outline some of the design and build process.

Specs and Features

Description

The evaporator was designed and built for approximately 25 - 50 taps, but can accommodate as little as 5 gallons of sap per batch in the main pan. In the peak of the season, with the help of a home-made reverse osmosis system, I was able to boil 60 gallons of sap from a single run without much difficulty.

I strongly recommend boiling the sap (or concentrated sap via an RO) in 5 gallon batches in the main pan to maximize efficiency and produce lighter colored and higher quality syrup.

The 5 gallon batches can be boiled down to less than 1 gallon and drawn-off into the mountable steam table pan and combined (up to 5 gallons / batches) and poured back into the main pan to be boiled down further. For reference, a 0.25" depth of sap left in the main pan is approximately 0.7 gallons.

The evaporator was also built with independent burner controls and cross braces in the frame to allow for boiling sap in a full size steam table pan for smaller sap volumes and finishing the syrup.

Additionally, a second steam table pan can be set inside and across the main pan to preheat the next batch of sap.

The frame is constructed of stainless steel "L" sections. The burner box is surrounded by firebrick and wrapped in galvanized steel.

The U-burners are from Hearth Product Controls and are tuned for efficency using Dante NG air/gas mixers. The piezoelectric igniters came from Brinkmann.

Construction Process

|

| Custom Hobby Evaporator |

Specs and Features

- Number of taps: 10 - 50

- Max main pan volume: 27 gallons (29.5" long x 21.5" wide x 10" deep)

- Recommended batch size: 5 gallons (sap or concentrate)

- Evaporation rate: 4 gallons/hour for 5 gallon batch

- Fuel type: Natural Gas (can be converted to propane with different orifice)

- Thermal output: 210,000 - 270,000 BTUs

- Burners: three (3) stainless steel U-burners

- Piezoelectric ignition

- Independent burner valves and air/gas mixing chambers

- Lid: stainless steel tiltable with steam catch channel

- Draw-off: gate valve over a mountable 6" deep full-size stainless steel steam table pan

- Steam table pan volume: 5 gallons

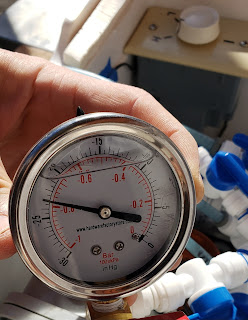

Update: later I added a burner under the front pan to increase the evaporation rate to 6 - 7 gph. I also built temperature and level controllers to automatically turn off the natural gas if the sap levels get too low or temperatures get too high.

Description

The evaporator was designed and built for approximately 25 - 50 taps, but can accommodate as little as 5 gallons of sap per batch in the main pan. In the peak of the season, with the help of a home-made reverse osmosis system, I was able to boil 60 gallons of sap from a single run without much difficulty.

I strongly recommend boiling the sap (or concentrated sap via an RO) in 5 gallon batches in the main pan to maximize efficiency and produce lighter colored and higher quality syrup.

The 5 gallon batches can be boiled down to less than 1 gallon and drawn-off into the mountable steam table pan and combined (up to 5 gallons / batches) and poured back into the main pan to be boiled down further. For reference, a 0.25" depth of sap left in the main pan is approximately 0.7 gallons.

The evaporator was also built with independent burner controls and cross braces in the frame to allow for boiling sap in a full size steam table pan for smaller sap volumes and finishing the syrup.

Additionally, a second steam table pan can be set inside and across the main pan to preheat the next batch of sap.

The frame is constructed of stainless steel "L" sections. The burner box is surrounded by firebrick and wrapped in galvanized steel.

The U-burners are from Hearth Product Controls and are tuned for efficency using Dante NG air/gas mixers. The piezoelectric igniters came from Brinkmann.

Construction Process

Comments

Post a Comment