3/16" Tubing Vacuum System

Building a temperature controlled maple tubing vacuum system

For the 2021 season we converted our operation to 3/16" tubing and built a temperature controlled vacuum system that uses a diaphragm pump.

The setup worked amazing and we averaged over 1 gallon of sap per tap each day, totalling 19 gallons of sap per tap and 0.275 gallons of syrup per tap on the season. In 2022 this system averaged over 0.35 gallons of syrup per tap on the season.

We used Leader clear check valve spiles with approximately 100 taps on a total of 6 lateral lines of tubing (~16 taps per line).

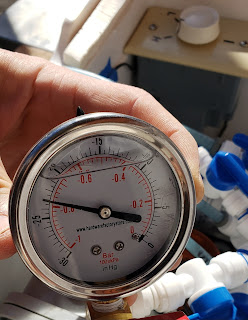

Our lateral lines have fairly good elevation drop to them (over 100 feet total and at least 10 feet from the final tap in most cases). This resulted in good natural vacuum and increased our sap yields. Additionally, the small diaphragm pump induced additional vacuum in the lines, further increasing sap yields. We consistently saw approximately 29 inHg of vacuum at the top of each line and 23 inHg at the pump when the sap was flowing.

|

| 23 inHg of vacuum at the pump |

In 2022 I also built a 2nd vacuum unit for another area of trees using a Shurflo 4008. This also worked exceptionally well, also yielding an average of 0.35 gallons of syrup per tap.

Both vacuum systems operate on the following basic principles:

- Turn on the diaphragm pump when temperatures rise above freezing to pull sap from the trees

- Turn off the diaphragm pump when temperatures fall below freezing

- Turn on a small heat source to prevent the insulated pump box (and the pump) from ever freezing

- Allow for sap to bypass the pump (via a check valve) in case of power or pump failure. I only have this feature on one of the units.

The vacuum system is comprised of the following basic components which are all readily available online from various outlets, including Amazon:

- An insulated box (a cooler works great)

- Electrical enclosure box for control system components

- Temperature controllers (W1209 model works great and is cheap)

- The diaphragm pump (Aquatec and Shurflo are very popular manufacturers)

- A manifold for connecting the tubing lines

- A strainer to protect the pump from ice

- A small heat source (silicon strip heater or light bulb)

Below is a schematic of the system we designed and built:

Below is a video explaining the system:

Below is an overview of the 12VDC Shurflo 4008 vacuum system:

The main parts are

(1) Shurflo 12 Volt RV Water Pump 3.0 GPM - 4008-101-A65 / E65 & strainer

(2) a 12V DC power supply (I used 15 amps)

(3) 2 of the W1209 temperature controllers (or similar 12v temp controllers - just make sure relay has 10-15 amps minimum)

(4) a heat source (I used watlow 100w strip heater I had)

(5) Coleman 16 qt cooler

(6) LMioEtool Enclosure with Clear Cover 8.7 x 6.7 x 4.3inch

https://a.co/d/6sjASI8

(7) vacuum guage

(8) 3/8 & 1/4 poly tubing, tees, valves etc. I used 3/8 for manifold and 3/8 x 1/4 tees with 1/4 valve for each lateral sap line

1/4 to 3/8 tees

https://a.co/d/911EmQs

(9) Barbed stem fittings: https://www.freshwatersystems.com/products/dmfit-stem-barb-straight-connector-1-4-od-stem-x-1-4-id-barb

Below is a video of how to install 3/16 tubing:

Below is a video of how to clean maple tubing lines after the season:

Two quick questions for you about your set-up, one, what did you use for your 12 vdc power supply? Do you have a part number? And where did you get your quick connects for your manifold? Thank you.

ReplyDeleteThis comment has been removed by the author.

DeleteThe 12vdc power supply I used is very similar to this one:

Deletehttps://www.amazon.com/dp/B01E6RMASC/ref=cm_sw_r_cp_apa_glt_fabc_TY77886BMYBTR5R17JHY

https://www.freshwatersystems.com/products/dmfit-stem-barb-straight-connector-1-4-od-stem-x-1-4-id-barb

DeleteNot sure if you got my first question, as I don't see it here?

ReplyDeleteI am building a small solar system like you have and am looking for, wondering where you got the bypass valve. I am too far away to turn a valve off and on, twice a day.

Thanks

The bypass check valve I used is available at freshwatersystems.com

ReplyDeletehttps://www.freshwatersystems.com/products/john-guest-check-valve-3-8-0-3-psi-crack-pressure

It has a crack pressure of 0.3 psi which equates to about 8.3 inches of water, which you should easily have in drop towards the end of your tubing setup.

I'll check it out.

DeleteThanks for your reply.

Happy syruping

LOL

You are very welcome and best wishes on the next season as well.

DeleteAny chance you could provide us with the 1209 settings you used for each...P0, P1 etc. New to this and trying to trouble shoot the unit. The vacuum piece without the controller is working great. thanks, Chris cyates72@yahoo.com

ReplyDeleteThere are manuals online to guide the setup. I would have to look at my exact settings but in general you want to have the unit turn off slightly below freezing and turn back on when slightly above freezing. It should be in cooling mode to do this.

Deletehttps://www.google.com/url?sa=t&source=web&rct=j&url=http://www.kelco.rs/katalog/images/17670.pdf&ved=2ahUKEwjhnbjKksH2AhUwlmoFHSysACMQFnoECAYQAQ&usg=AOvVaw1o0xvrWLCkFvjFS__tzhGL

This looks great. What fittings did you use and is there a diagram? Do you have a complete list? Also, I found a 12-volt diaphragm pump (32-80 psi), so I can go all 12 volts. Do you see any problems? The temperature controllers you use are great.

ReplyDeleteThanks

Abbott

There is a diagram provided in the post. Most fittings are 3/8 push to fit. I use 3/8 x 3/8 x 1/4 tees to adapt to 1/4 for the ball valves and the 3/16 barb x 1/4 stem fittings to connect the tubing. I have a 2nd unit that uses a 12v shurflo 4008 pump and it works fantastic. I only used the 120v aquatec pump because I had it on hand from a prior RO build.

DeleteIs there a reason to use 3/16 instead of 5/16 if mechanical vacuum will be used? I was under the impression that 3/16 was used for natural vacuum situations.

ReplyDeleteI have a good amount of elevation change from top to bottom of my lines and decided to use 3/16 for natural vacuum gains in addition to the mechanical vacuum the small diaphragm pumps add. An aquatec 8800 or shurflo 4008 can pull 10 inhg dry, and over 20 inhg with fluid however neither move large amounts of air very effectively. 5/16 lines contain much more air per linear foot and I believe these factors would have resulted in lesser performance/yield than the 3/16 lines.

DeleteHi, do you have any sort of step by step guide for assembling this unit for those of us who are not electrically inclined? Thanks for sharing this great system.

ReplyDeleteI do not, but offer a simpler solution for the temperature controllers that was not available when I built these systems:

Deletehttps://a.co/d/1fGQ4rm

This can independently control the pump and a heater. Just plug power supply into one outlet and heater in the other and set the temperatures.

This is great information. I have 110V power where my pump will be located. Any reason to use 12V instead?

ReplyDeleteMy system also has 3/16" tubing and lots of elevation drop, but also more taps ~450. Should I consider a larger GPM pump than the 4008?

12v motors tend to last longer. I just use a 12v power supply plugged into 110v power and it works great. For 450 taps you probably want to break that across 3 different pumps. You can have a single control system and power supply (if sized correctly) that controls all 3 pumps in a single box, but that will help keep maximum vacuum and flowrate on heaviest run days.

Delete